Welcome to visit our factory. Schedule a visit today!or Get in Touch

Welcome to visit our factory. Schedule a visit today!or Get in Touch

8.75m x 2.4m x 4.3m

Sleeps up to 4 to 6 People

Shower

Toilet

The Ruapehu tiny homes on wheels is a twin mezzanine Tiny Homes on wheels with a larger bathroom and kitchen than most other models. The kitchen and bathroom are under the two mezzanine levels meaning they are at either end of the Tiny Homes on wheels, rather than beside each other in most models. There is space for a washing machine in the bathroom, which features a stylish benchtop sink and birch ply cupboard space and extensive storage. Steam is eliminated in the bathroom with built-in showerdome to keep the moisture in and a full-size bathroom fan.

The kitchen extends down both sides of the Tiny Homes on wheels offering plenty of countertop space and lovely bifold windows in front of the stainless-steel sink. A staircase accesses the main mezzanine level with a ladder accessing the other.

The Ruapehu is 8.75m long, 2.4m wide and weighs in under the legal limit of 3,500KG. It can be towed by most recent model full-size Utes.

As with all our Tiny Homes on wheels designs, we have never made the same model twice, as our clients add, change and modify the layout they like the best to create their perfect dream Tiny Home.

Boson Experience

We are a professional manufacturer of tiny houses and modular houses. To date, we have designed and produced dozens of houses (with or without wheels) for buyers in various countries. All modular houses we manufacture can be either mounted on or detached from the chassis we produce.

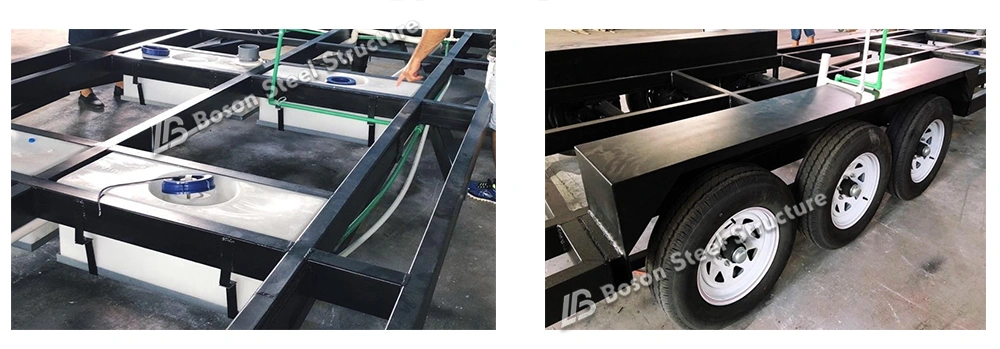

Our automotive engineers specialize in the design of professional-grade chassis. Tailored to different vehicle models, both the counterweight configurations and chassis structures are customized accordingly. We incorporate AL-KO rubber torsion shafts, which boast a maximum load-bearing capacity of up to 6,000 kg. For corrosion protection, all chassis undergo either hot-dip galvanization or are coated with weather-resistant polyurethane anti-rust spray—two treatments that ensure long-term resistance to environmental wear.

For the chassis, we utilize high-strength automotive-grade steel; for the housing frame, we utilize light steel systems, steel pipes, and glulam. By combining these multiple materials, the design not only substantially reduces overall weight but also enhances structural stability.

We select multiple types of high-quality interior materials, and the entire decoration construction is undertaken by skilled specialized carpenters. To ensure long-term durability, we only use premium weather-resistant sealants from renowned international brands: WACKER (Germany) and Sika (Switzerland).

The exterior cladding adopts three key materials: Aluminum Alloy Panels, Weather-Resistant Timber Claddings, and Colorbond Multi-Material Composite—all selected for their durability and compatibility with exterior environments.

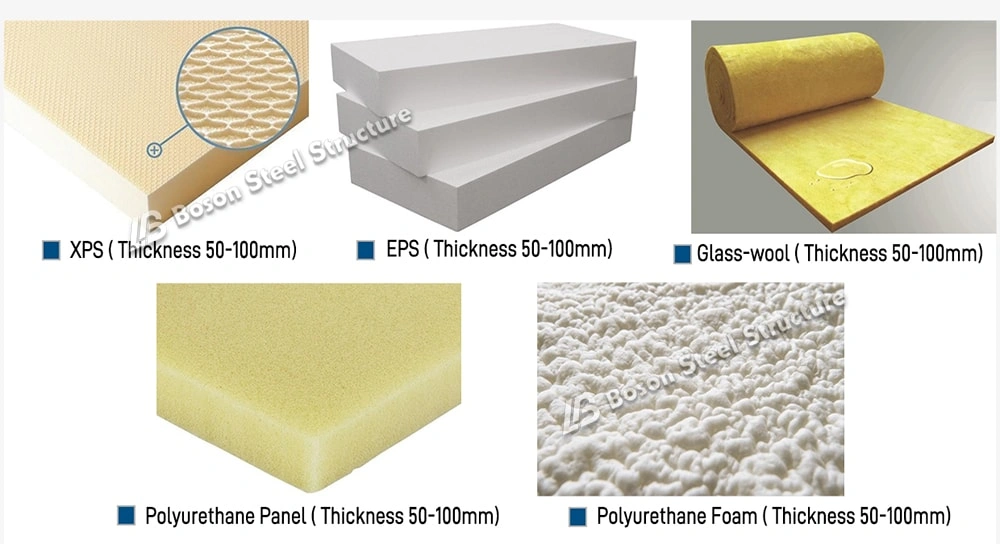

To ensure optimal adaptability to different regional climates, we provide a comprehensive selection of insulation materials—such as polyurethane insulation, PIR insulation, and glass wool insulation—tailored to meet site-specific thermal requirements.

The doors and windows feature an exclusive broken-bridge aluminum system. To enhance structural integrity and water tightness, all units come fitted with extended edges and water-retaining strips; additionally, the glass is specified as double-glazed or triple-glazed LOW-E glass for superior thermal insulation.

We are well-versed in and fully comply with electrical wiring construction standards across various nations. Moreover, to ensure alignment with local regulations and operational safety, all power cords, receptacles and switches, distribution boxes, and circuit breakers selected meet the certification requirements of the destination country.

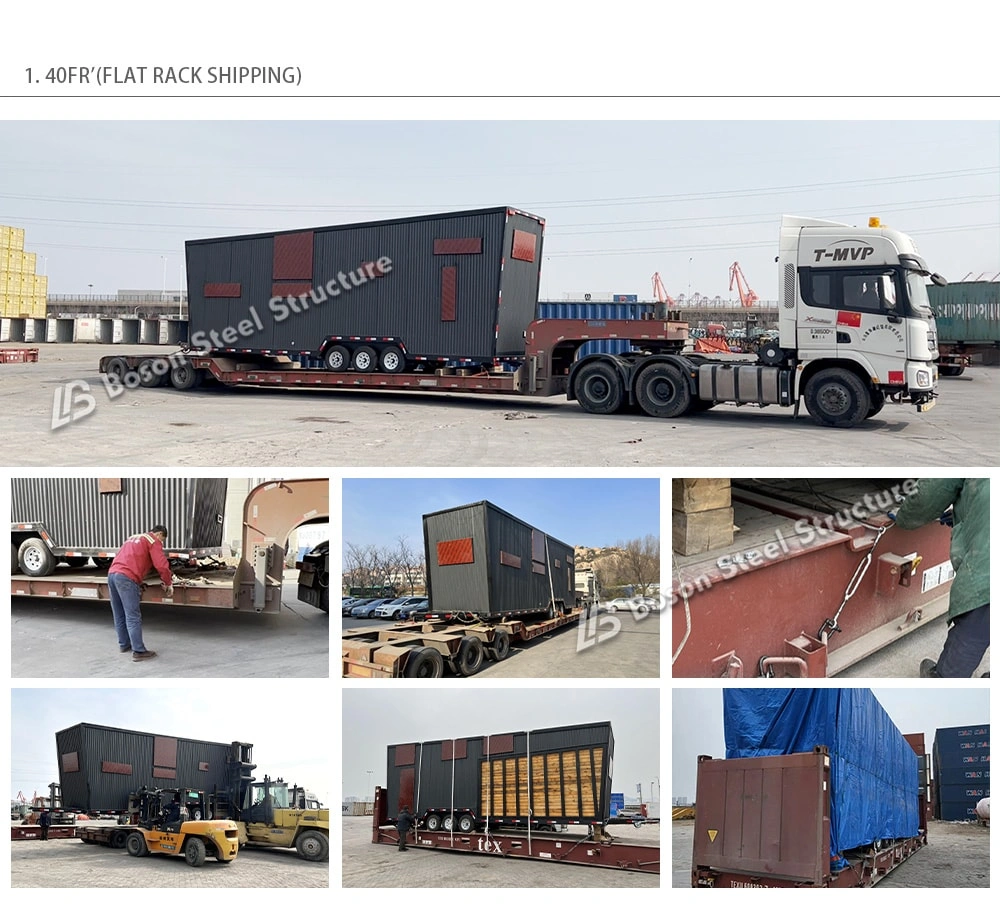

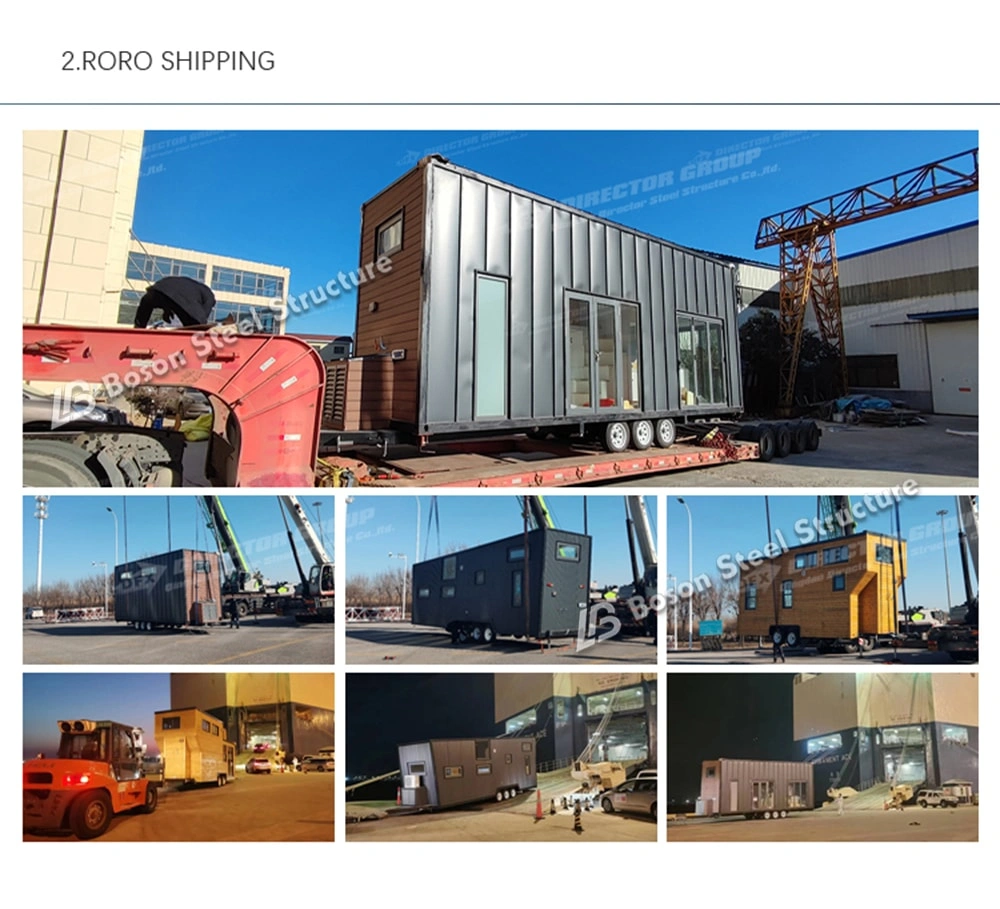

Depending on the destination country, we provide two modes of transportation: ro-ro shipand frame container, We will choose different modes of transportation according to thefreight rate and time.

To ensure premium quality and compliance across all systems, we partner with renowned global suppliers for key components:

● Mechanical Performance: Torsion axles and brake systems are sourced from AL-KO, a leader in automotive/engineering mechanical components.

● Roofing & Wall Durability: For roofing and walls, we use Colorbond materials and aluminum alloy roofing supplied exclusively by BlueScope (Australia), a trusted name in high-performance building materials.

● Electrical Safety & Compliance: Electrical components—including distribution boxes (Siemens, Schneider) and circuit breakers (Siemens, Schneider)—meet strict industry standards. Our wires, lighting systems, and plumbing systems further comply with SAA, CE, and WATERMARK certifications, ensuring alignment with global safety norms.

● Thermal Insulation: Insulation materials are procured from Owens Corning and the Knauf Group, two industry pioneers in energy-efficient insulation solutions.

● Windows & Doors: Aluminum alloy doors and windows are equipped with double-glazed or triple-glazed insulated glass, certified to either Australian standards or CE, balancing thermal efficiency and regulatory compliance.

Fill out the form below in detail to enable our engineering team to design a precision solution for your project. With over 15 years of global expertise in steel buildings, we'll analyze your requirements and provide:

Technical drawings compliant with international standards (EN/AISC/CE/)

Material optimization for warehouses, hangars, or agricultural facilities

Budget breakdown with logistics support

Your inquiry will be prioritized - expect a personalized proposal from our steel specialists within 24 business hours.