Welcome to visit our factory. Schedule a visit today!or Get in Touch

Welcome to visit our factory. Schedule a visit today!or Get in Touch

One 40HQ can lold 10 sets

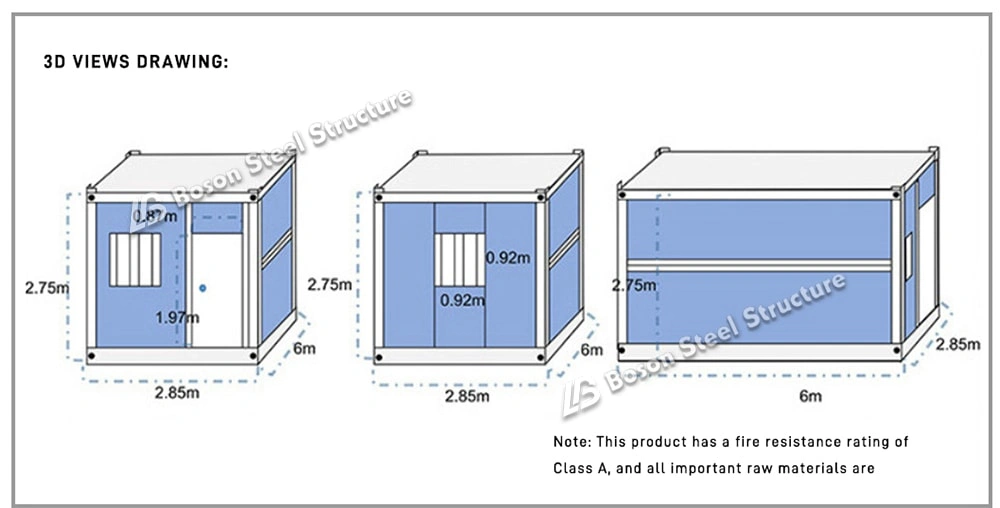

Expanded size:L5850*W2438*H2500

Folded Size:L5850*W2438*H440mm

Weight: 1260KGS

Lifespan: 15~20 years

Z-shape Foldable Container House

Foldable Container House | Versatile & Customizable Space Solution

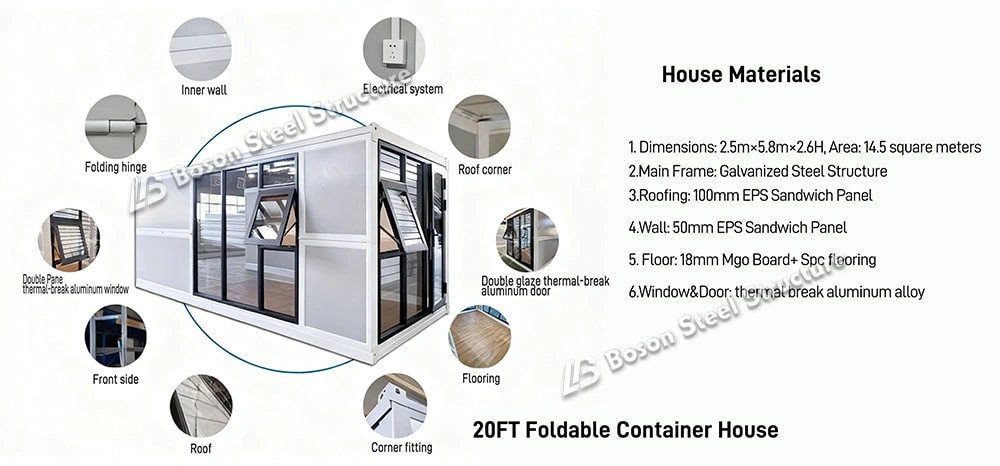

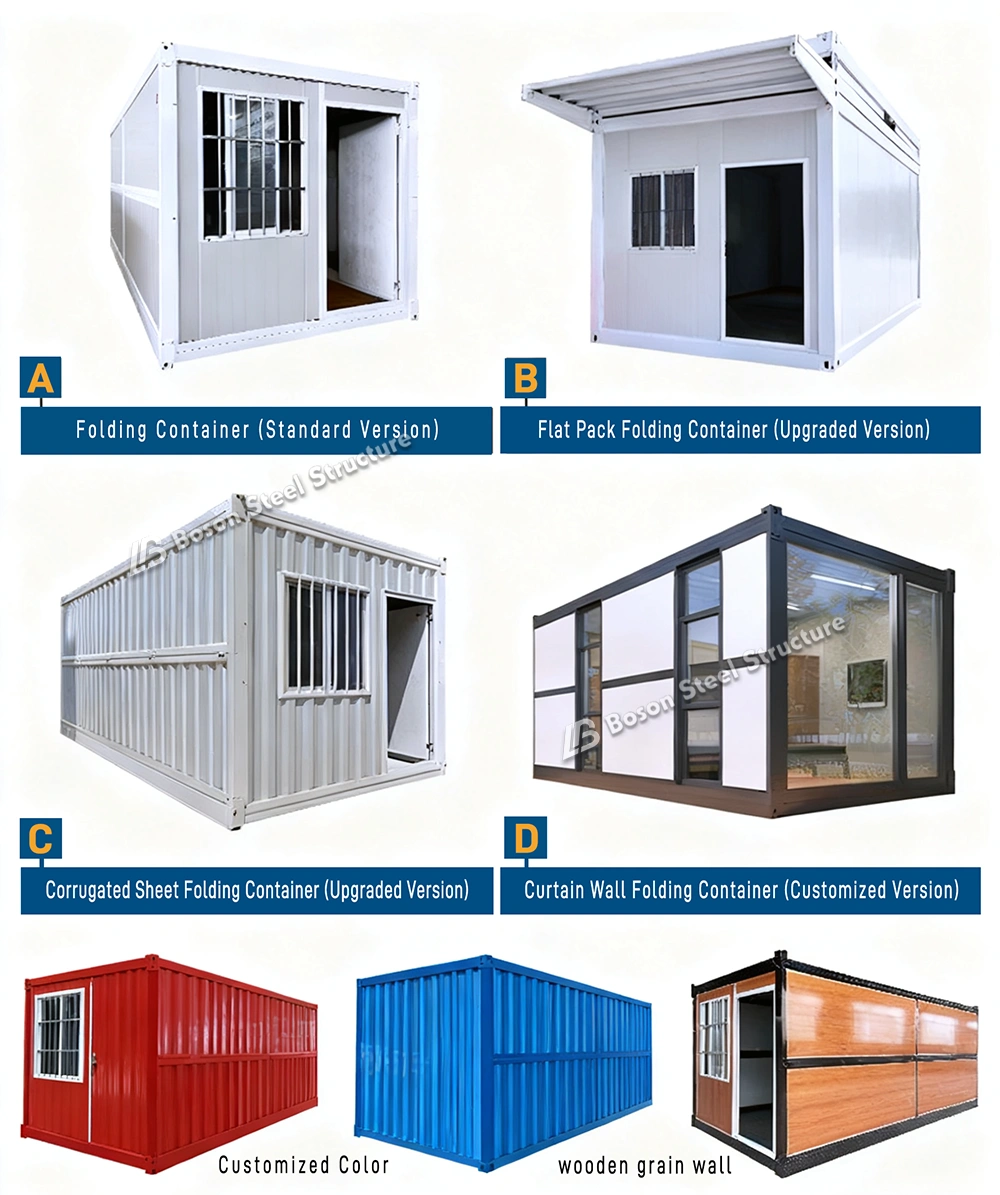

Discover our innovative Foldable Container House, engineered for maximum adaptability and durability. Built with a galvanized cold-rolled steel frame, it delivers superior structural strength and reliable performance across various applications. Whether for residential, commercial, or office use, this space solution combines comfort, safety, and modern design.

Key Features:

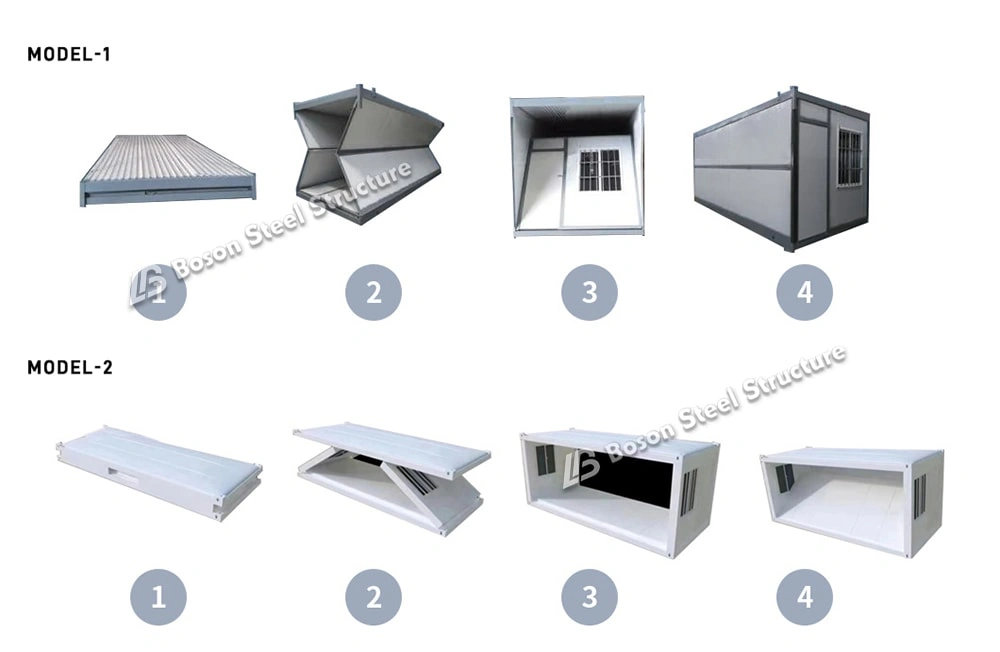

● Efficient Folding Design: Set up your foldable container house in just 5 minutes. Its flat-pack system allows easy transport and storage, making reuse and relocation effortless.

● Stackable & Multi-Level Configurations: Create larger layouts by stacking multiple units. Ideal for expanding space needs without compromising stability.

● Customizable & Sustainable: Tailor the interior to your needs with flexible design options. Built with high-quality, eco-friendly materials for long-lasting use.

Why Choose Boson Foldable Container House?

As a prefabricated container house, it is industrially produced to ensure consistent quality and a long lifespan. Experience the future of modular living and working spaces—where efficiency, customization, and sustainability come together.

|

Product Name |

Foldable Container House |

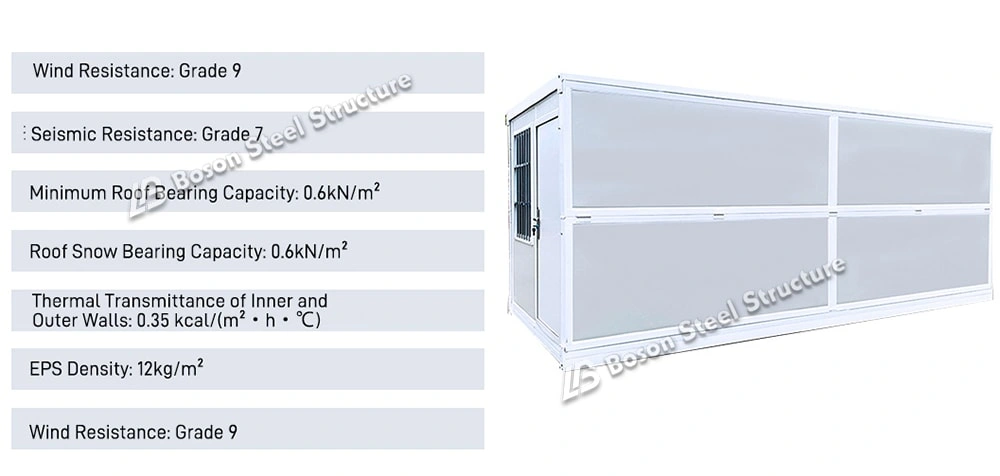

Wind speed |

45m/s. |

|

Material |

Heavy duty galvanized steel powder coated frame |

Roof |

3-4mm Hot galvanized steel structure with 4 corner casts and |

|

Beam&Column |

Specification 50mm*160mm |

Size |

5830mm*2500mm*2470mm |

|

Wall&insulation |

75mm EPS/rock woll sandwich panel, or customized PU sandwich panel |

Decorative Wall |

Optional PVC timber-grain exterior cladding for added appeal |

|

Bathroom |

Including toilet, wash basin,shower room, vanity mirror, |

Steel grade |

GB、ASTM、EN、JIS、ISO.etc |

|

Color |

White, Charcoal or according to customer's requirement. |

Usage |

House,Office, Dormitory, Shop, Bar, Emergency Room, Disaster Relief Room |

|

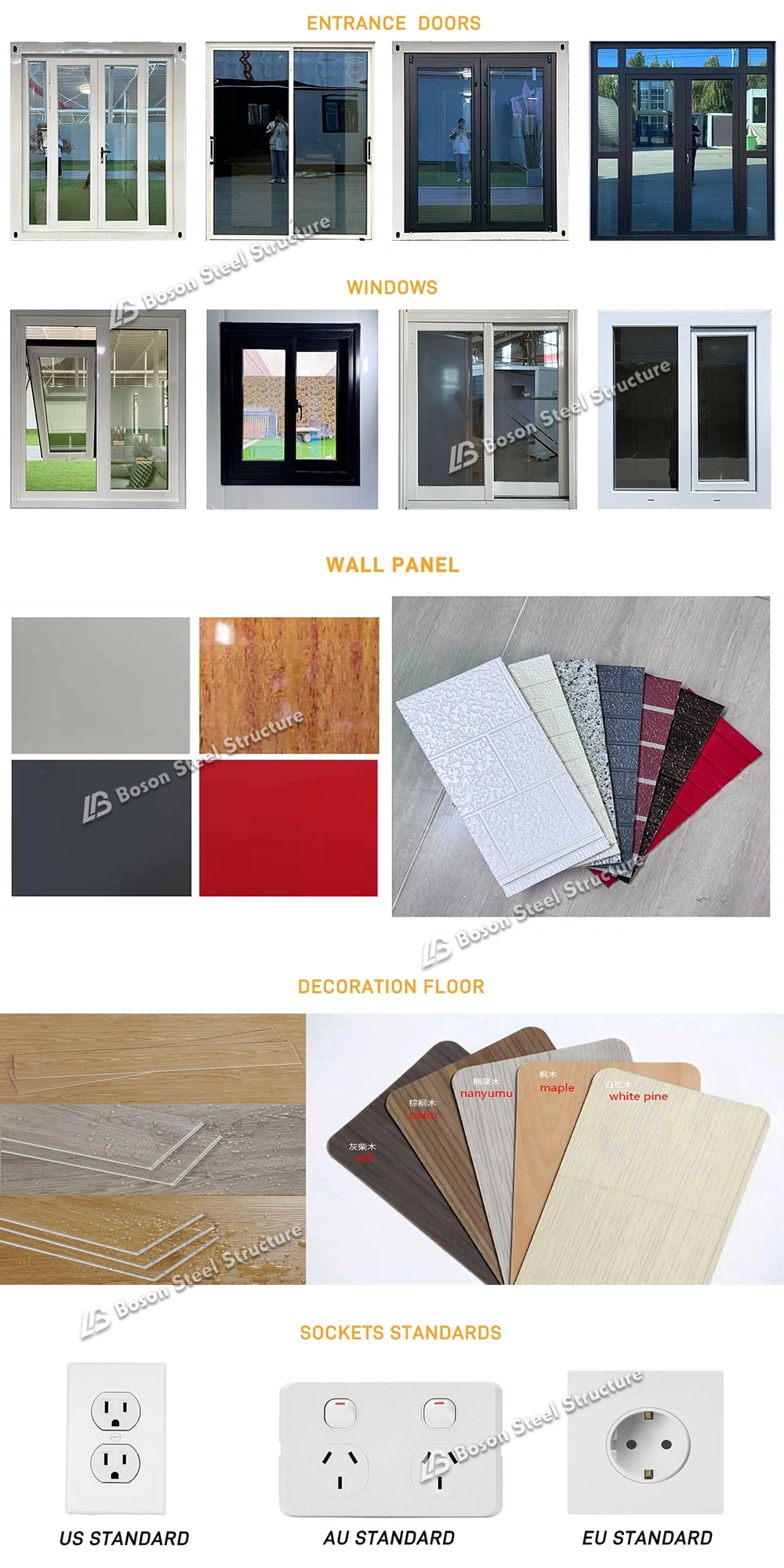

Door |

Steel door,Aluminum double glass door,Cut-bridge aluminum double glass door |

Sub Floor |

18mm fibre cement subfloor board base, pre-fitted to steel frame |

|

Flooring |

PVC/SPC/wooden flooring |

Electricity |

CE,SAA,UL and customized |

|

Window |

PVC/Aluminum alloy window, louver window |

Approx. Weight |

1.26 tones per unit |

|

Layout |

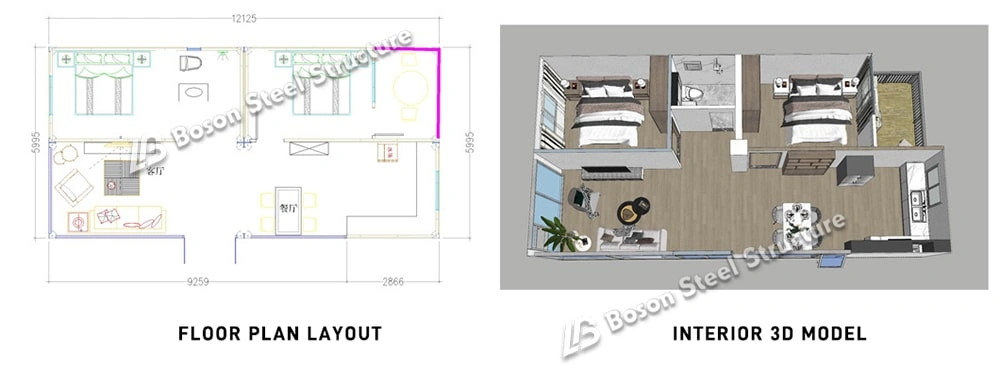

From 1 bedroom to 4 bedrooms, 1 kitchen, 1 or 2 bathroom, |

||

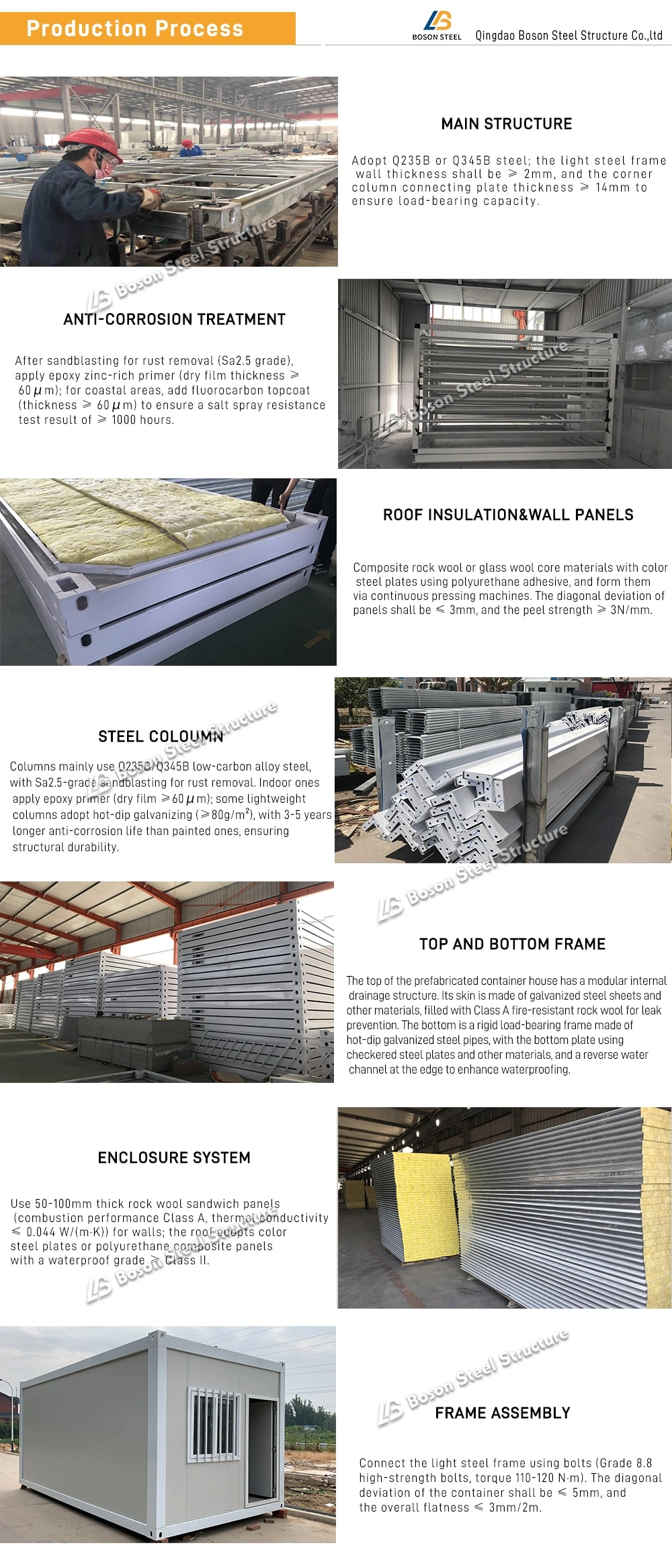

Based on the customer’s application scenarios (e.g., residential, office, emergency housing) and site conditions, 3D modeling is conducted using BIM technology or CAD software to determine the container dimensions (common sizes: 20ft/40ft), spatial layout (e.g., multi-container combination), and functional configurations (e.g., integrated modular bathrooms/kitchens). The design must comply with standards such as Modular Container-type Steel Structure Buildings (T/CAS 546), with key considerations including seismic performance (additional diagonal braces for seismic fortification intensity ≥ Grade 7) and fire safety spacing (distance between containers ≥ 6 meters).

|

Comparison Table: Z-shape vs. Standard Foldable Container House |

||

|

Z-shape Foldable Container House |

Standard Foldable Container House |

|

|

Folding Principle |

Walls rotate in a "Z-shaped" motion and stack onto the base frame. |

The entire structure compresses vertically, like an accordion. |

|

Transport Efficiency |

Good; designed for convenient packing and turnover. |

Excellent; folds down to under 45cm, allowing ~16 units on a 17.5m truck. |

|

Setup/Dismantling Speed |

Designed for a simplified process, but actual speed needs verification. |

Extremely Fast; 2 people can set up or pack a unit in 5 minutes. |

|

Structural Design |

Uses a U-shaped channel, pulley, and support wheel system for stability and smooth folding. |

Relies on a robust frame; the folding mechanism is more straightforward. |

|

Technical Highlights |

Patented design focusing on reliability, stability, and preventing misalignment during folding. |

Mature technology focused on cost-effectiveness and functional simplicity. |

|

Best Use Case |

Projects requiring high-frequency, long-distance relocation and high reliability. |

Cost-sensitive temporary projects (e.g., construction camps) requiring rapid deployment. |

Before loading, all internal components of the foldable container house (like kitchen cabinets, fragile sanitary ware, glass items, and furniture) are wrapped in eco-friendly cartons and fixed with straps. Then, the entire container house is covered with anti-collision foam to prevent damage during transit. After that, it’s loaded into the shipping container as shown in the process.

Fill out the form below in detail to enable our engineering team to design a precision solution for your project. With over 15 years of global expertise in steel buildings, we'll analyze your requirements and provide:

Technical drawings compliant with international standards (EN/AISC/CE/)

Material optimization for warehouses, hangars, or agricultural facilities

Budget breakdown with logistics support

Your inquiry will be prioritized - expect a personalized proposal from our steel specialists within 24 business hours.