Welcome to visit our factory. Schedule a visit today!or Get in Touch

Welcome to visit our factory. Schedule a visit today!or Get in Touch

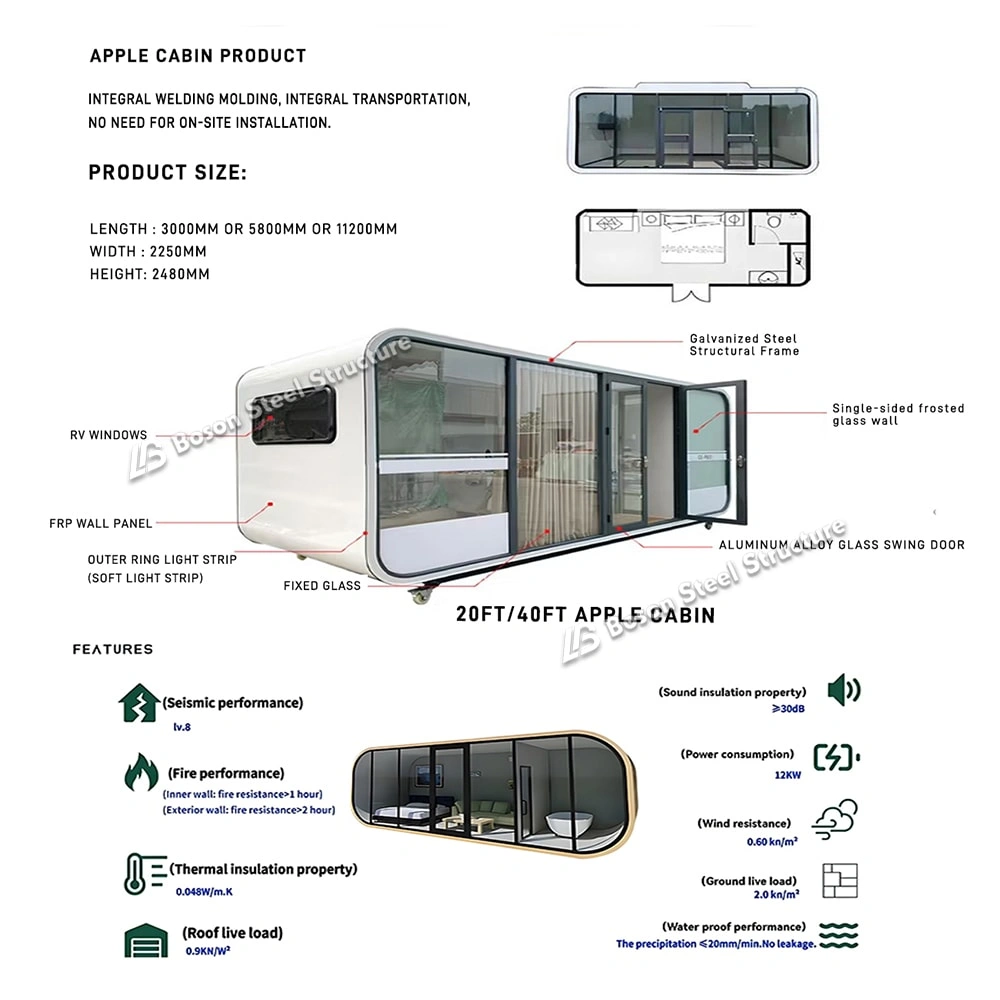

Floor area: 25.87m²

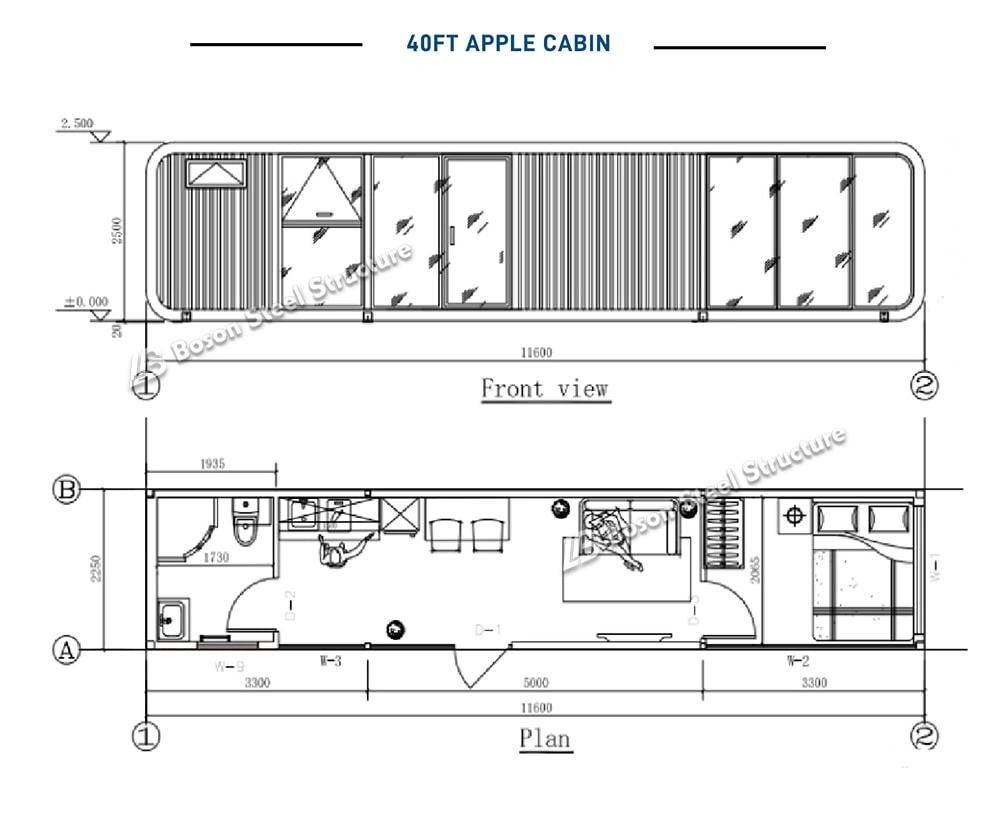

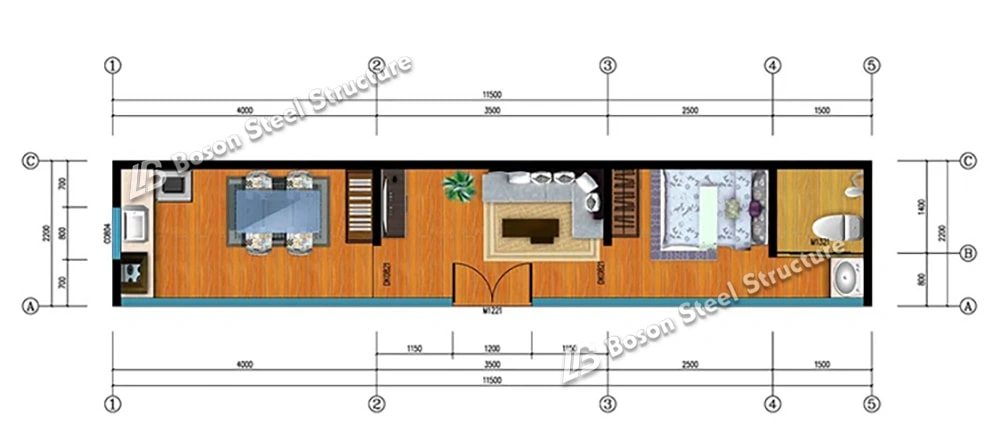

Exterior size: L 11.5m * W 2.25m * H 2.5m

Loading:1set/40HQ

Lifespan: 20 years more

40FT Apple Cabin Tiny House

Apple Cabin Tiny House is a compact yet thoughtfully designed space with a smooth, curved shape inspired by an apple. The curved structure maximizes space, creating an open and airy feel while maintaining a warm and inviting atmosphere.

● Apple Cabin: Where Camping Meets Luxury Stay

● Merges camping’s outdoor experience with hotel/homestay tranquility.

● Offers superior comfort.

● Customizable interiors and layouts.

● Fully welded, solid & stable structure.

● Perfect for couples/private use.

● Fully prefabricated with decoration, ready to use by connecting to outdoor utilities.

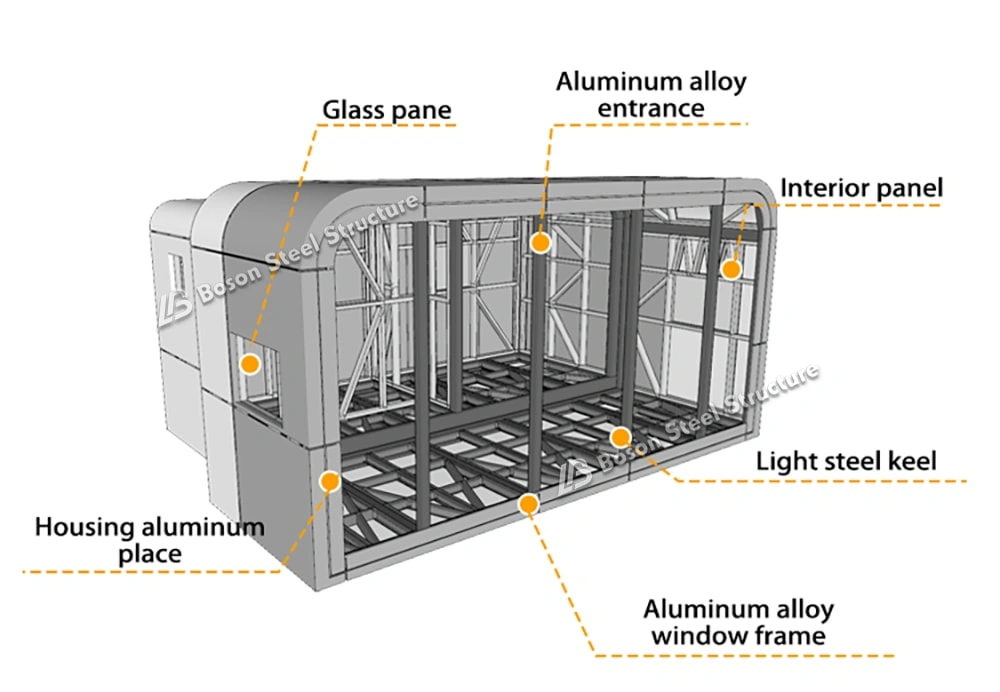

Engineered for strength and long-lasting durability, the main frame of the Apple Cabin Tiny House is constructed using high-grade galvanized steel. The structure includes robust 80×160×2.0mm and 50×100×1.2mm main beams, with eight precision-fitted pieces ensuring overall stability and structural integrity. Designed to support the pod’s load efficiently, this frame provides a rock-solid foundation that stands resilient in diverse environments.

40FT APPLE CABIN

| Main Exterior Details | ||||

| Main Framing | Hot-Dip Galvanized Steel Frame Structure, Thickness: 4mm | Model No. | Apple Cabin Tiny House | |

| Exterior Shell | Aluminum Alloy Single Panel, Thickness: 2.0mm; Surface: Metal Baking Paint Process | Entrance Lock | Hotel-Grade Outdoor Waterproof Smart Door Lock | |

| Thermal Insulation | Heat Preservation And Waterproof Layer (Flame-Retardant, High-Density, High-Strength Grade A+; Eco-Friendly And Odorless Polyurethane Insulation Layer | Electrical Equipment Room | For Air Conditioner/Water Heater | |

| Glass Curtain Wall | 6+12A+6 Insulated Tempered Glass | Panoramic Balcony | Balcony With Laminated Tempered Glass | |

| Exterior Led Ambient Lights | ||||

| Fine Interior Decoration Details | ||||

| Ceiling | High-End Custom Bamboo Fiber Ceiling | Flooring | Spc Flooring | |

| Interior Wall | Wood Veneer Composited Wallboard | Lighting | Ambient Surrounding Light Strips+Recessed Downlighting | |

| Curtain | Electric Curtain Track+Full Blackout Curtain System | |||

| Electrical And Plumbing Details | |||

| Cables | Whole-House 10mm² Cable Entry, 8-Core Network Cable | Water Heater | Integrated Electric Water Heater (1500W) |

| Pipes | Pvc Insulated Wiring Pipes+Whole-House Explosion-Proof And Pressure-Resistant Water Supply And Drainage Pipes | A/C | Central Air Conditioning |

| Socket | 5-Pin Socket / 3-Pin Socket (Relevant National Standards) | Switch | Usb Panel (Relevant National Standards) |

| Bathroom And Hardware Details | |||

| Door | One-Way Frosted Tempered Glass) | Toilet | High-End Smart Toilet |

| Shower | Multifunctional Showerhead | Tile | Ceramic Tile |

| Vanity | Washbasin / Sink / Mirror / Cabinet / Floor Drain |

Heater |

5-In-1 Bathroom Heater (Lighting, Ventilation, Heating, Air Exchange & Warming) |

| Product Accessories | Smart Control System | ||

| Transport | Lifting Rings / Transport Fasteners / Connectors | Access Control System | Power On By Card Insertion / Power Off By Card Removal |

| Supports | Foot Supports | Smart Control System | Smart Curtain Control, Smart Voice System |

| Ladder | Three-Step Entrance Ladder | ||

Apple Cabin ’s interior combines durability with style. It features 16mm cement fiber board flooring topped with customizable SPC flooring and elegant skirting. Walls are finished with eco-friendly bamboo fiber boards, offering waterproof and anti-corrosive protection. A 30mm XPS insulation layer ensures thermal comfort, complemented by a double-glass door for efficiency and soundproofing.

Original manufacturer of space capsules. The factory covers an area of about 100,000 square meters and has a monthly production capacity of 150 units. It supports OEM design, contract manufacturing, and new product development.

Before loading, all internal components of the Apple Cabin Tiny House (like kitchen cabinets, fragile sanitary ware, glass items, and furniture) are wrapped in eco-friendly cartons and fixed with straps. Then, the entire container house is covered with anti-collision foam to prevent damage during transit. After that, it’s loaded into the shipping container as shown in the process.

Fill out the form below in detail to enable our engineering team to design a precision solution for your project. With over 15 years of global expertise in steel buildings, we'll analyze your requirements and provide:

Technical drawings compliant with international standards (EN/AISC/CE/)

Material optimization for warehouses, hangars, or agricultural facilities

Budget breakdown with logistics support

Your inquiry will be prioritized - expect a personalized proposal from our steel specialists within 24 business hours.